Advanced Abrasives Corporation offers a premium line of superabrasive products customized for high-pressure/high-temperature sintering applications for PCD and PcBN (polycrystalline diamond and polycrystalline cubic boron nitride).

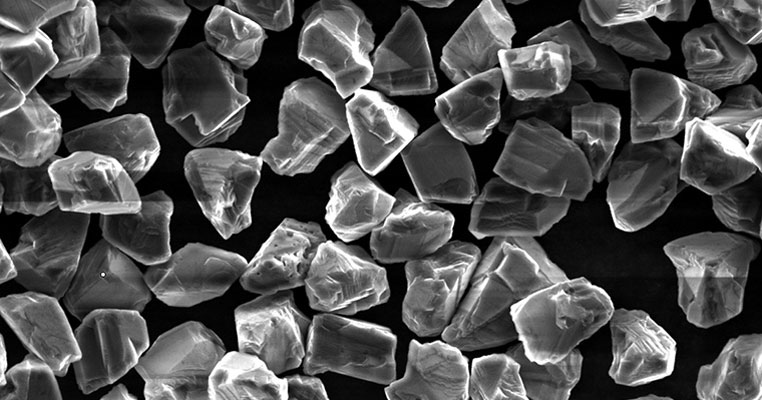

During high-pressure sintering, a percentage of material fractures and reveals new surfaces that were previously intrinsic to the crystal. If the material has high internal impurities, they will reveal themselves at the surface as the crystals fracture. These impurities may result in inefficient sintering/bonding due to contaminant migration into the catalytic/solvent system and/or between the diamond-to-diamond interface. A low level of intrinsic impurities is essential in optimizing the sintering process. Advanced Abrasives selects premium feedstock crystals with the lowest level of intrinsic impurities currently available.

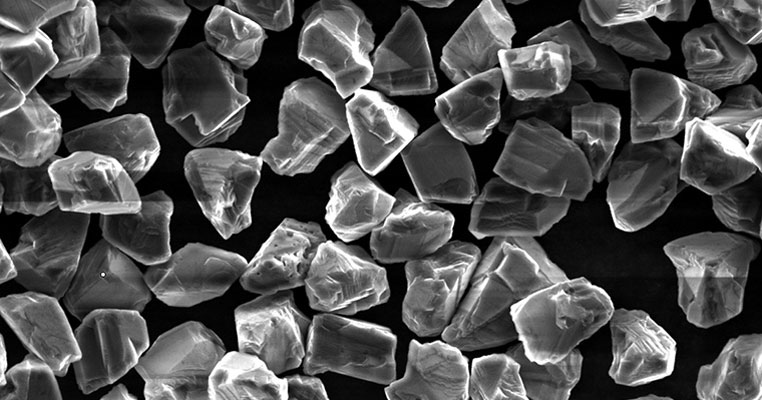

Proprietary milling techniques are used to size reduce, and to shape the material, ensuring consistent morphology with each and every batch of material.

Additionally, our cleaning process incorporates a proprietary chemical/mechanical cleansing technique. This enables us to reduce or eliminate unwanted organics/elements and control the topography of the crystal. Surface characteristics can range from smooth to completely etched, depending on customer requirements.

For the sizing of our superabrasive product, we use many different classification techniques. Each technique is monitored and controlled with strict statistical process control guidelines. We custom grade all products for sintering applications based on each customer’s unique abrasion/impact requirements, and we can provide compounded / stratified blends. Each step of the grading process is controlled and monitored. Advanced Abrasives Corporation uses 100% lot inspection to ensure consistency from batch to batch.

Final inspection consists of many measures to ensure the highest quality products possible. We monitor particle size distribution (PSD) using the Microtrac S3500, Coulter Multisizer III, CPS Differential Sedimentation, SEM/TEM, or optical light microscope. After PSD analysis, the material goes through an extensive ion reduction process and a surface purification process. The final product is certified using Ion Chromatography, Inductively Coupled Plasma, and DC Arc instruments. Typical levels of the most critical ions/elements that can hinder the sintering process are held below 1ppm*.

COMPOUNDED AND LAYERED SINTERING FEEDSTOCK PRODUCT

Advanced Abrasives also offers a complete line of compounded and layered sintering feedstock products. We can develop unique compounded or stratified blends for customer applications based on press platform and loading techniques that will:

- Increase abrasions and/or impact resistance

- Enhance thermal stability via a high diamond-to-diamond bond ratio, resulting in stronger TSP

- Optimize wear resistance

- Increase the surface quality of wire

- Extend tool, cutter, or die life

Benefits of Choosing Our Premium Sintering Feedstock

When it comes to enhancing the performance, durability, and overall quality of your abrasives and tools, our Premium Sintering Feedstock is an invaluable asset. This top-tier product is specially designed for a range of applications, including Diamond & cBN Tool Manufacture, Electronics & Photonics, Optical Polishing, Sample Preparation, and Sintered Tool Manufacture. Dive into the benefits of our premium sintering feedstock products.

Increased Abrasion and Impact Resistance

Our Premium Sintering Feedstock is designed to increase abrasion and impact resistance, helping your tools withstand the toughest conditions and the most demanding jobs.

Enhanced Thermal Stability

Our feedstock enhances thermal stability with a high diamond-to-diamond bond ratio, resulting in stronger Thermally Stable Polycrystalline (TSP) diamonds. This makes it ideal for applications where heat resistance is crucial.

Optimized Wear Resistance

Our Premium Sintering Feedstock also optimizes wear resistance, extending the lifespan of your tools and reducing the need for frequent replacements. This can lead to significant cost savings over time.

Improved Surface Quality

The use of our feedstock in wire manufacturing can significantly enhance the surface quality. This results in smoother finishes and improved precision in end products.

Extended Tool, Cutter, or Die Life

By increasing the durability and wear resistance of your tools, cutters, or dies, our Premium Sintering Feedstock can substantially extend its service life. This means fewer disruptions in your manufacturing processes and more efficient operations.

Applications: Where Our Sintering Feedstock Shines

Our premium sintering feedstock is ingeniously designed to cater to a wide array of applications across various industries. Its high-quality and performance-enhancing properties make it an ideal choice for diverse uses.

Diamond & cBN Tool Manufacture

Our sintering feedstock plays a crucial role in the manufacture of tools such as Blades, Burrs, and Grinding Wheels. Its ability to increase abrasion and impact resistance makes it ideal for creating durable and long-lasting tools.

Electronics & Photonics

In the world of electronics and photonics, our feedstock is used for Device Mounting and Silicon Wafer applications. It enhances thermal stability, making it perfect for high-heat resistance applications.

Optical Polishing

Our feedstock proves to be invaluable for Precision Glass applications within the field of Optical Polishing. Its property to improve surface quality makes it a top choice for achieving superior finishes.

Sample Preparation

In the realm of Sample Preparation, particularly in Metallography and Petrography, our sintering feedstock is highly sought-after. Its optimized wear resistance helps in extending tool life, ensuring efficient sample preparation processes.

Sintered Tool Manufacture

Our feedstock is indispensable in the production of PDC Cutters in Sintered Tool Manufacture. The enhanced thermal stability offered by our feedstock results in more robust and durable tools.

Superfinishing

In the field of Superfinishing, particularly in Lapping Film applications, our sintering feedstock is a game-changer. Its ability to increase surface quality contributes to achieving smoother finishes, making it an ideal choice for superfinishing processes.

Get Your Premium Sintering Feedstock Today

Our Premium Sintering Feedstock, a product of meticulous research and development, is designed to meet the most demanding needs of high-pressure/high-temperature sintering applications. Customized for PCD and PcBN manufacturing, this feedstock crystal boasts the lowest level of intrinsic impurities available.

Thanks to our proprietary milling techniques and chemical/mechanical cleansing techniques, we ensure consistent morphology while reducing unwanted organics and elements. Moreover, we understand that each customer’s requirements are unique, and thus, we custom-grade our product based on your specific abrasion and impact needs.

Advanced Abrasives Corporation invites you to reach out to us for more information or to speak with one of our premium sintering feedstock experts. Elevate your sintering applications with our fantastic team or explore additional solutions such as our custom tailored powders or coated powders.