Introduction

Advanced Abrasives offers an extensive lineup of diamond powder products comprising various grades of metal bond catalyst monocrystalline diamond (MDP), resin bond monocrystalline diamond (RDP), polycrystalline diamond (PDP) and natural diamond (NDP) to meet a wide range of applications in industry from feedstock for sintering large polycrystalline diamond pieces to abrasives for fine grinding and polishing. All of these products undergo rigorous processing and quality assurance steps to ensure that they meet or exceed industry standards. They are provided in jars as dry powder for the larger abrasive particle sizes and in bottles containing a dispersion in DI water carrier for the finer powders to prevent agglomeration. By special request, these powders can also be provided in a carrier fluid of your choice.

In each case, lot information for; particle size distribution, particle morphology characterization and chemical analysis is available upon request.

Advanced Abrasives diamond powders are available in numerous standard abrasive size selections from 25 nanometers up to 30/40 mesh, each with a tightly held particle size distribution. And for specific applications requirements, we are able to provide non-standard sizes and customized particle size distributions.

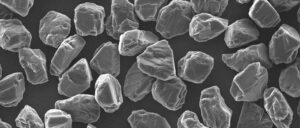

The below listed characteristics of MDP – N make this line the perfect product for High Pressure/High Temperature applications, semiconductor and microelectronics applications. MDP(N) is also used in abrasive wheel fabrication and high precision lapping and polishing applications. Available in multiple particle sizes ranging from 25nm up to 30/40 mesh, each nominated size with a tightly held particle size distribution through stringent grading and oversize control.

Features

- Tight particle size distribution

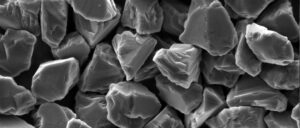

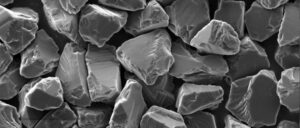

- Blocky and etched surface

- Stringent oversize control

- Surfaces cleaned to extremely low levels of elemental impurities and ionic content

- Specific feed crystal source and monitoring

- Majority of sizes are from our proprietary Mesh-to-Micron process

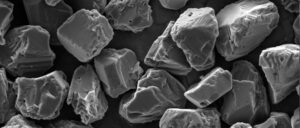

MDP is the popular choice for a majority lapping and polishing applications when the characteristics of MDP(N) are not required. Available in multiple particle sizes ranging from 25nm up to 30/40 mesh, each nominated size with a narrow particle size distribution through our grading and oversize control process.

Features

- Narrow particle size distribution

- Blocky Shape

- Oversize control

- Surfaces cleaned

MDP-IR is the economical alternative where precision surface finishes are not required. This material is not recommended for any type of bonded or sintered abrasive application. Available in multiple particle sizes ranging from 50nm up to 30/40 mesh, each nominated size with a standard particle size distribution.

Features

- Standard particle size distribution

- Irregular with Blocky Shapes

- Oversize monitored

- No gross contamination

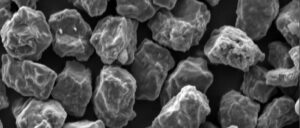

RDP is the recommended product for machining many types of ceramic, glass and tungsten carbide. This material is ideal for all vitrified, phenolic and polyimide bond systems. Available in multiple particle sizes ranging from 50nm up to 30/40 mesh.

Features

- Narrow particle size distribution

- Irregular Shape

- Oversize control

- More friable than MDP

PDP is made up of nano-crystallites that give it a unique break down mechanism which allows new cutting edges to be exposed creating a self-sharpening characteristic. PDP is used primarily for lapping and polishing sapphire, ruby, metallographic samples, fiber optics and ceramics along with disk texturing, head polishing and lapping of substrates. Available in multiple particle sizes with center points ranging from 25nm up to 15µm, each nominated size with a tightly held particle size distribution through our stringent grading and oversize control.

Features

- Tight, customized particle size distribution

- Blocky particles

- Stringent oversize control

- Low scratch count

- High material removal rate

The natural alternative to synthetic diamond. NDP exhibits a high surface finish while maintaining an above average stock removal rate. NDP is widely used in the gem/diamond polishing markets but it is also used for general lapping and polishing applications. Larger crystal NDP is used for single point tool applications and in some cases for diamond die applications.

Features

- Standard particle size distribution

- Irregular with Blocky Shapes

- Oversize monitored

- No gross contamination

For many applications, agglomeration can have a serious negative impact on the process. Agglomeration occurs when extremely clean particles are dried and their surfaces bond together with such force that it is impossible to get them separated again. This inability to re-disperse the particles is most prevalent in sizes 0.5µm and below.

Advanced Abrasives offers this material in de-ionized water straight from the grading process which means no agglomeration of particles. In many cases, the end use process needs agglomerate free diamond powder but without it being in a D.I. water carrier as adding water to the process is not an option. In these cases we offer to flip the diamond powder from the D.I. water carrier into a compatible component carrier for your process without every drying the diamond.

Our diamond powder is supplied pre-wetted in the following standard micron sizes; 0.5µm, 0.375µm, 0.25µm, 0.125µm, 0.1µm, 0.05µm and 0.025µm