Diamond Compounds and Paste

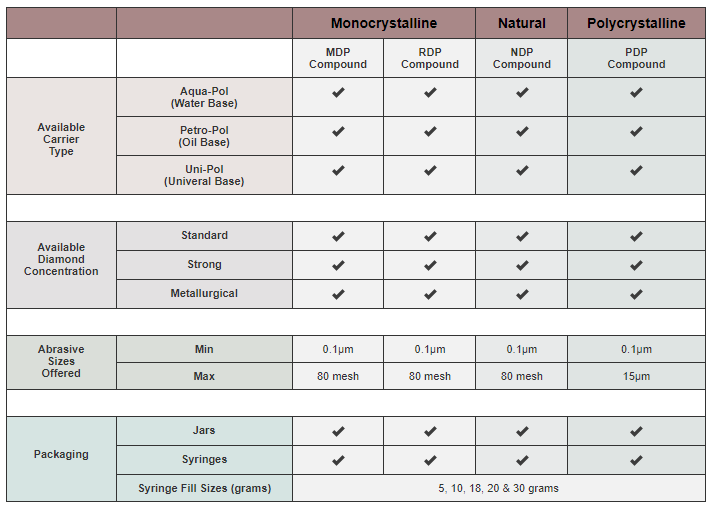

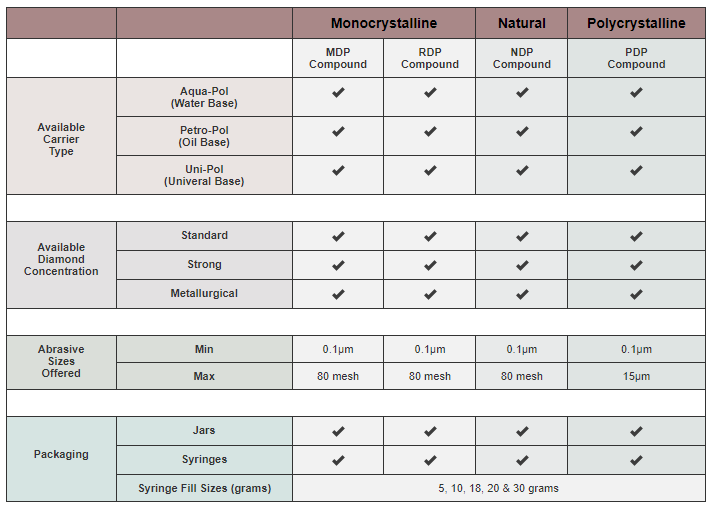

Advanced Abrasives diamond compounds (pastes) are formulated using our tightly graded diamond powders and proprietary carriers for fast cutting action, excellent surface finish, and easy cleanup. They are available as natural diamond (NDP), synthetic monocrystalline diamond (MDP and RDP), or polycrystalline diamond (PDP) paste. Each comes with your choice of three carrier types and three concentration levels of the abrasive particle to ensure you find a product that matches your application needs.

Our compounds are color-coded according to the particle size as an identification aid when using finer grades in succession and are available in jars or syringes for easy application. If you want to sharpen and polish a large selection of different surfaces and materials, turn to our diamond-lapping compounds for unmatched efficiency and reliability. Or explore other formulations like our cubic boron nitride to expand your uses of our product selections.

What is Diamond Compound Used For?

Diamond compounds are remarkable tools for smoothing and polishing materials of any hardness. From metals to plastics, it can be used to create glossy finishes by virtue of the hardest mineral available today. Diamond compounds help individuals in various industries save cash and ensure a smooth and well-polished surface. They’re used for a variety of needs, including:

- Polishing and grinding jewelry or gems and removing scratches and damage.

- Grinding compound used for tungsten carbide blades, optical molds, injection molds, etc.

- Optical lenses, quartz wafers, sapphire, and semiconductors.

- Polishing and grinding magnetic minerals, ceramics, and cemented carbide.

- The diamond polishing compound is also used to finalize medical or dental equipment (i.e., dentures).

Diamond Paste Polish

Advanced Abrasives diamond paste polish is a water-based compound containing sub-micron, monocrystalline diamond powder, and proprietary lubricant. It’s designed for polishing or lapping all types of materials, including metals, composites, ceramics, glasses, and plastics. The paste also provides premium cutting action and a solid, smooth finish. Our diamond paste is available in a range of particle sizes and is versatile enough for use in custom projects or some of the more industry-standard needs.

Use our diamond polishing compound for manual polishing, machine polishing of molds, polishing coatings, and surefire adhesion to felt or wooden laps. It can also be used for lapping or grinding and provides the following advantages:

- Provides fast cutting action and the best possible surface finish.

- Easy application and diamond lapping compound

- Tightly graded diamond powders ensure consistent and reliable results.

- Available in many options, including Monocrystalline, Natural, Polycrystalline, and advanced carrier types, sizes, and concentrations.

- Diamond paste and Diamond compounds are made from the strongest mineral available, making them useful for all types of surfaces.

Secure Your Abrasive Compound Paste From Our Diamond Lapping Paste Suppliers

For a premium polish, quality stock removal, and the best benefits from your purchase, try securing your diamond compounds and diamond paste from Advanced Abrasives. Customers can contact our team today to explore more of our diamond lapping compound and paste or look at some of our additional offerings.

Pair your diamond paste with abrasive lapping products, or check out our diamond suspensions and slurries. Advanced Abrasives is a leading provider for all industries worldwide, including the USA, Asia, and Europe. Discuss with our technical experts to determine whether a monocrystalline, natural, or polycrystalline compound suits your needs.