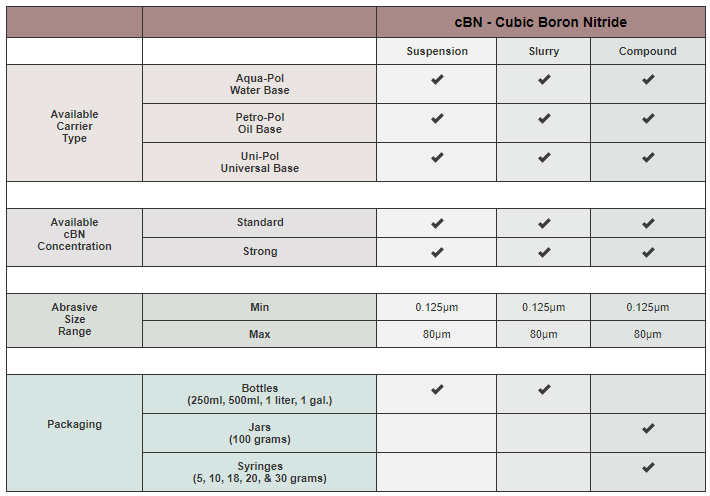

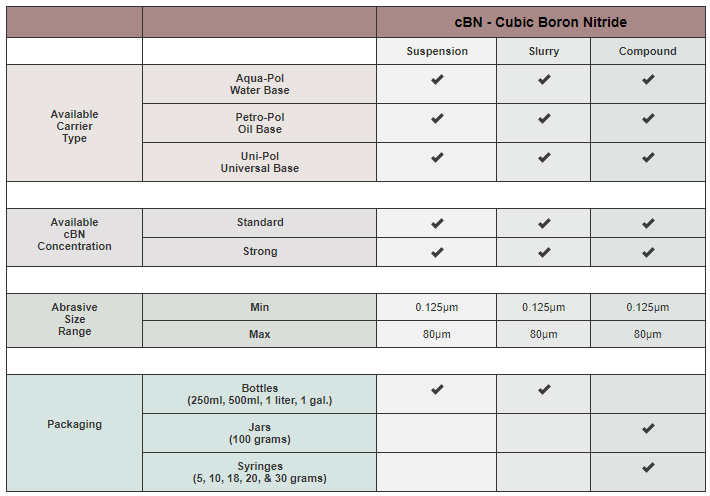

Our high-quality cBN cubic boron nitride powder is combined with our proprietary water, oil, or universal carrier bases to provide cBN Aqua-Pol, cBN Petro-Pol, and cBN Uni-Pol slurries, suspensions and compounds available in abrasive sizes ranging from 0.125µm to 80 mesh.

The Versatility of Cubic Boron Nitride

Cubic Boron Nitride (cBN) is a synthetic crystalline material second only to diamond in hardness. It is renowned for its durability, thermal stability, and chemical inertness, making it a highly desirable superabrasive for industrial applications.

cBN’s hardness is surpassed only by diamond, making it incredibly resistant to wear and tear. This makes it an ideal choice for tools and equipment expected to withstand harsh conditions and heavy usage. Additionally, cBN maintains its integrity under high temperatures, particularly in an environment where iron or nickel is present. This makes it highly suitable for machining ferrous materials where diamond would oxidize and degrade.

It also provides resistance to chemical interaction with ferrous materials at high temperatures, allowing it to provide a clean cut without the risk of reaction or adhesion. This ensures a smooth, high-quality finish in machining applications.

Incorporating cubic boron nitride into your processes can significantly enhance efficiency, productivity, and product quality. Discover the power of cBN for your operation with Advanced Abrasives.

cBN Applications and Industry Uses

Cubic boron nitride (cBN) powder is highly valued across various industries due to its exceptional hardness, thermal stability, and chemical inertness. Here’s a list of some of the key applications and industry uses of cubic boron nitride powder:

- Grinding Ferrous Metals: cBN abrasive tools deliver excellent grinding performance, especially for high-hardness, tough materials.

- Superabrasive Grinding Wheels: cBN grinding wheels have unique advantages in grinding materials that are difficult to cut due to their high strength and hardness.

- Dicing Blades: cBN is used in the production of dicing blades, which are used for cutting or slotting semiconductor wafers, silicon, glass, ceramic, etc.

- Polishing and Lapping Applications: Micron-sized cBN powders are used for polishing and lapping applications, improving the surface integrity of ferrous materials.

- Abrasive Machining Processes: cBN is an integral component in industrial abrasive machining processes like grinding and honing.

- Grinding Technical Blades: Abrasive tools made of cBN grains and vitrified bonds are widely used for shaping technical blades.

- Fine Machining Applications: cBN powder is used in fine machining applications, and it’s also suitable for manufacturing Polycrystalline Cubic Boron Nitride (PcBN) and abrasive paste.

The Advantages of Cubic Boron Nitride

With its unique properties, cBN powder is a game-changer for industries requiring high-performance abrasives and cutting tools. Some of the key advantages of incorporating cBN powder into your operations include:

Superior Hardness

cBN powder boasts a level of hardness second only to diamond. This makes it incredibly resistant to wear and tear, extending the lifespan of tools and equipment.

Exceptional Thermal Stability

Unlike diamond, cBN maintains its integrity under high temperatures, especially in environments where iron or nickel is present. This thermal stability makes it ideal for machining ferrous materials where diamond would oxidize and degrade.

Chemical Inertness

The chemical resistance of cBN powder is unmatched. It ensures a clean cut without the risk of reaction or adhesion when interacting with ferrous materials at high temperatures. This results in a smoother, higher-quality finish in machining applications.

Versatile Applications

Thanks to these qualities, cBN powder is widely used in grinding wheels, cutting tools, coatings, and other high-performance applications. Whether you’re hard machining, grinding hardened steels, or finishing high-temperature alloys, cBN can significantly enhance efficiency, productivity, and product quality.

Improved Efficiency

Using cBN powder in your tools can lead to faster cutting and grinding speeds, reducing downtime and increasing productivity. Its durability also means less frequent tool changes, further boosting operational efficiency.

Secure Cubic Boron Nitride for Your Industry Applications Today

Experience the power of Cubic Boron Nitride (cBN) in your operations today. cBN is the key to unlocking higher productivity, efficiency, and quality in your manufacturing processes. Harness the transformative potential of cBN powder and take a bold step forward in your industry.

Contact Advanced Abrasives Corporation today and let our team guide you on the journey to superior performance and quality with cubic boron nitride, cubic boron nitride powders, or coated powders.