Polishing Cloths & Pads

Advanced Abrasives provides a specialized line of polishing cloths and pads designed to support precision surface finishing across metallographic preparation, industrial manufacturing, and advanced material processing. These products complement our diamond and oxide polishing formulations and are selected to perform consistently from fine grinding and intermediate polishing through final surface refinement. Every polishing cloth and pad we offer is selected for process control, material compatibility, and repeatable surface finish performance.

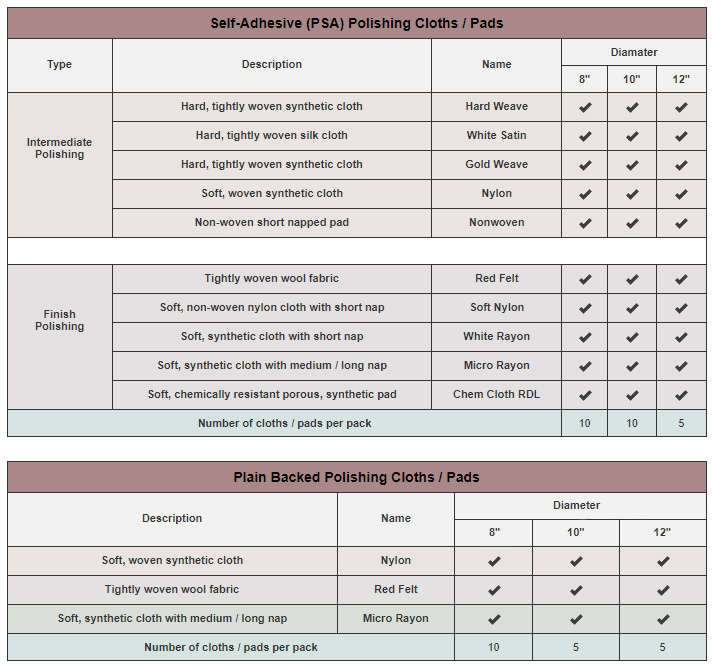

Our polishing cloths and pads are available with pressure-sensitive or plain backing, in standard 8-inch, 10-inch, and 12-inch diameters, and integrate seamlessly with common laboratory and production machine platforms. Each option supports demanding surface-finishing processes for diamond and oxide polishing.

Precision Polishing Cloths for Controlled Surface Finishing

Polishing cloths and pads play a critical role in controlling surface roughness, minimizing contamination, and supporting accurate measurement during surface finishing and metallographic analysis. The selection of the correct cloth affects material removal rates, wear characteristics, and final surface finish, especially when using diamond suspensions, oxide suspensions, colloids, and other polishing compounds.

Our range supports applications across manufacturing, research, quality control, and failure analysis, where consistency and surface integrity matter as much as throughput. These polishing surfaces are used in mechanical and automated processes involving grinding, polishing, burnishing, and surface treatments.

Applications Across Materials and Industries

Advanced Abrasives polishing cloths and pads support a wide range of materials and processes, including:

- Steel and stainless steel component preparation

- Aluminium and anodized aluminium plate finishing

- Copper, tin, and platinum alloys

- Ceramic and gemstone polishing

- Glass, thin film, and electrode preparation

- Surface preparation for coating, plating, and thermal spraying

Industries served include aerospace, automotive, electronics, medical devices, optics, jewelry manufacturing, and advanced surface finishing operations.

Self-Adhesive Polishing Cloths and Pads

Our self-adhesive polishing cloths and pads are designed for secure adhesion to polishing platens, allowing stable operation during high-precision processes. PSA backing supports repeatable positioning, fast changeovers, and consistent results when transitioning between polishing stages.

Intermediate Polishing Cloth Options

Intermediate polishing cloths balance material removal with surface refinement. These options work well with diamond polishing compounds during transitions between grinding and finish polishing, as well as with abrasive lapping films and polishing extenders and lubricants. Available intermediate polishing surfaces include:

- Hard Weave, a hard, tightly woven synthetic cloth for controlled cutting action

- White Satin, a tightly woven silk cloth supporting uniform diamond distribution

- Gold Weave, a hard synthetic option designed for consistent surface contact

- Nylon, a soft, woven synthetic cloth suitable for varied surface finishing needs

- Nonwoven pads with a short nap structure to support uniform abrasive interaction

These polishing cloths are commonly used when preparing metal surfaces such as steel, aluminium, copper, and stainless steel for subsequent polishing steps or surface treatments like electroplating and passivating stainless steel processes.

Finish Polishing Cloth Options

Finish polishing focuses on achieving low surface roughness Ra and controlled surface finishes suitable for analysis or final product use. These polishing cloths are effective for oxide suspensions, colloidal silica, and fine diamond compounds. Finish polishing options include:

- Red Felt, a tightly woven wool fabric offering stable polishing behavior

- Soft Nylon, a non-woven microfiber style cloth with short nap

- White Rayon, a soft synthetic cloth supporting fine surface finish control

- Micro Rayon, a longer-nap microfiber cloth for final polishing stages

- Chem Cloth RDL, a chemically resistant, porous synthetic pad for specialized processes

These materials support optical polishing applications involving glass, ceramic, silicon wafers, and sensitive metallic surfaces where surface contamination, lint control, and adhesion behavior are critical.

Plain-Backed Polishing Cloths and Pads

Plain-backed polishing cloths and pads provide flexibility for users who prefer manual mounting or non-adhesive setups. These options integrate well with laboratory workflows, sample preparation, and customized polishing systems.

Plain-Backed Cloth Options

Our plain-backed polishing surfaces include:

- Nylon, a soft, woven synthetic cloth for general polishing

- Red Felt, a wool-based option supporting controlled polishing action

- Micro Rayon, a longer-nap microfiber cloth designed for fine surface finishing

Material Compatibility and Process Control

Selecting the correct polishing cloth or pad depends on material type, polishing compound, and target surface roughness. Advanced Abrasives supports customers working with a wide range of substrates and processes.

Metals and Alloys

Polishing cloths are frequently used for surface finishing of metal components, including steel, aluminium, copper, stainless steel, gold, platinum, and sterling silver. Applications include surface preparation before coating, plating, welding inspection, and corrosion analysis. These polishing surfaces support processes such as:

- Grinding and intermediate polishing prior to electroplating

- Surface preparation for powder coating and thermal spraying

- Surface treatments related to electrophoretic deposition and electrolyte exposure

- Wear evaluation and surface roughness measurement

Non-Metallic Materials

Polishing cloths and pads are also used for glass, ceramic, silicon, and composite materials. These applications often involve thin-film preparation, laser ablation analysis, and surface inspection for laser engraving or other laser processes. Proper cloth selection helps control surface contamination, fiber transfer, and polishing consistency during sensitive surface finishing operations.

Integration With Advanced Surface Finishing Processes

Advanced Abrasives polishing cloths and pads are integrated into complex surface-finishing processes used across modern manufacturing and technology-driven environments.

Compatibility With Advanced Processes

Our polishing surfaces support integration with:

- Vibratory finishing systems

- Mechanical surface finishing and burnishing

- Laser engraving and laser ablation analysis

- Plasma-based surface treatments

- Sandblasting and spray preparation steps

- Surface preparation prior to sealant or coating application

They are frequently used as part of a comprehensive surface-finishing workflow that includes grinding, polishing, cleaning, and final inspection.

Performance Factors That Matter

Key performance considerations include:

- Adhesion stability during polishing cycles

- Controlled fiber structure to manage lint and contamination

- Consistent wear behavior across multiple samples

- Compatibility with diamond, oxide, and colloidal polishing compounds

These factors improve surface finishes, reduce rework, and enable accurate measurement of surface roughness and Ra evaluation.

Designed for Accuracy and Repeatability

Advanced Abrasives’ polishing cloths and pads are selected with accuracy as a priority. From metallographic laboratories to high-volume manufacturing environments, these products deliver repeatable results across a range of surface-finishing processes.

They are used to prepare surfaces for inspection, evaluate coating adhesion, conduct corrosion testing, and measure surface roughness on materials such as anodized aluminum, anodized aluminum plate, white anodized aluminum, stainless steel, and ceramic substrates. Our products support ultra-metal finishing and superfinishing requirements, where surface quality, cleanliness, and process control influence final performance.

Work With Advanced Abrasives

If your surface finishing process requires polishing cloths and pads that support accuracy, material compatibility, and consistent performance, Advanced Abrasives is ready to help. Our team works directly with customers across manufacturing, research, and industry to match polishing surfaces with the right polishing compounds and process parameters.

Contact Advanced Abrasives to discuss your application, request technical guidance, or explore available polishing cloth and polishing pad options. When you are ready to move forward, our team can help you identify the right products and guide you through the next steps so you can confidently add to cart and integrate these polishing solutions into your process.