Oxide Polishing Compounds

While the finish from diamond polishing to 3µm or 1µm is perfectly adequate for many metallurgical testing/quality assurance-related applications, it may not be sufficient for achieving publication-quality micrographs. In these cases, oxide polishing is required.

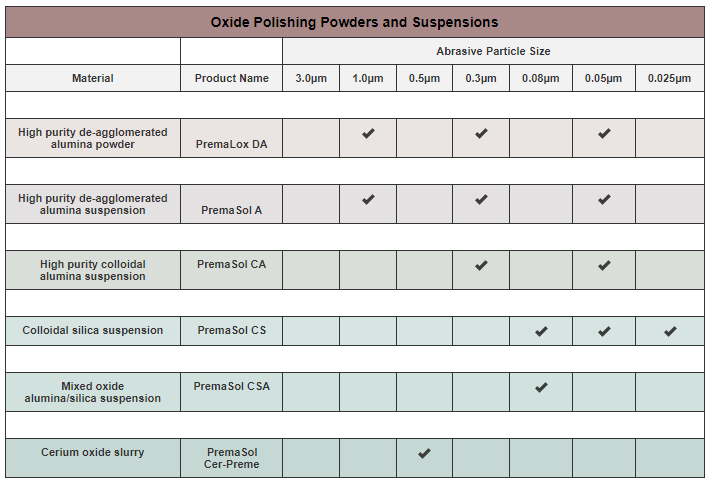

Advanced Abrasives Corp provides a selection of metallurgical quality, de-agglomerated alumina powders, and suspensions ideal for ferrous applications. Also offered is a high-quality, soft-drying, colloidal silica suspension ideal for non-ferrous applications. Our mixed oxide suspension provides the benefits of both colloidal silica and alumina. Our cerium oxide slurry is particularly effective for polishing soft metals and specimens containing glass.

Perfecting Metallography Processes With Oxide Polishing Products

Enjoy precision, efficiency, and unparalleled quality with Advanced Abrasives. Our Oxide polishing products are game-changers in the realm of metallography processes. They are crafted to deliver superior performance, ensuring your metallographic preparations are nothing short of perfect. They offer various sizes, from 3.0 µm to 0.025 µm, offering versatility that all will surely enjoy. You’ll find our innovative oxide polishing powders and suspensions to be the key to unlocking new levels of brilliance in your work.

Oxide Polishing Powders

These powders are used in polishing to achieve fine finishes in material analysis. The combination of gentle abrasion and chemical activity helps remove all scratches and deformation, resulting in a smooth, flawless surface. Specific types, such as our PremaLox DA de-agglomerated alumina powder, are lauded for their ability to deliver superior results. These powders adhere to the highest quality specifications and are integral to the final polishing of metallographic specimens.

Oxide Polishing Suspensions

Advanced Abrasives Corporation offers a variety of oxide polishing suspensions that play a critical role in metallography. These suspensions combine gentle abrasion and chemical activity to completely remove all scratches and deformation, resulting in a perfectly smooth surface. Our product range includes high-purity de-agglomerated and colloidal alumina suspensions. In addition, Advanced Abrasives also offers a colloidal silica suspension that is excellent for chemo-mechanical polishing. All our polishing suspensions are designed to adhere to the highest quality specifications, making them an integral part of achieving superior results in metallographic specimen preparation.

Embrace the Unique Benefits of Using Our Oxide Polishing Powders and Suspensions

Specifically engineered for excellence, our products offer a unique blend of fine abrasion and chemical activity, ensuring complete removal of scratches and deformation for pristine surface quality.

Oxide suspensions deliver an impeccably smooth, distortion-free finish. They are designed to remove the final layer of surface deformation, preparing your sample optimally for further analysis. Additionally, our oxide polishing powders and suspensions adhere to the highest quality specifications, ensuring you get consistent results every time. From engaging research to quality control and production, you can expect products that deliver accurate and reliable outcomes.

Cerium Oxide Slurry for Metallographic Preparation

PremaSol Cer-Preme Cerium Oxide Slurry is a superior solution explicitly designed for metallographic preparation. This high-quality slurry is formulated with cerium oxide, renowned for its exceptional polishing properties. The PremaSol Cer-Preme slurry offers quality performance in the final polishing stages, delivering a mirror-like finish while maintaining precise surface integrity. Its stable, non-crystallizing formula ensures consistent results, and its 0.5 µm size is perfect for various applications.

Characteristics of Effective Oxide Polishing Compounds

Not all oxide polishing compounds are created equal. The most effective formulations combine strategic chemical properties with exceptional physical performance. When you’re selecting an oxide compound, look for these critical characteristics:

Consistency is key. A waxy consistency allows for smooth, controlled application across different surfaces. Compounds like tin oxide and chromium oxide offer unique benefits depending on your specific project requirements. The best compounds create minimal heat during application, preventing surface damage to delicate materials like copper, silver, brass, and stainless steel.

Particle size and distribution play a massive role in your finishing quality. Smaller particles produce a finer finish, while larger particles work faster on tougher surfaces like granite and hard metals. Professional-grade compounds provide a balanced approach, allowing you to quickly remove material while maintaining an incredibly smooth surface. Color and purity also matter more than most people realize. High-quality oxide compounds should have a uniform color and minimal impurities. This ensures consistent performance whether you’re polishing woodworking tools, blades, or intricate stone surfaces.

Common Mistakes to Avoid with Oxide Polishing Compounds

Many professionals and hobbyists make critical errors that compromise their finishing results. Here are the most common pitfalls to dodge:

Quantity control is crucial. Too little compound means inadequate coverage, while excessive amounts create unnecessary mess and waste. Learn to apply a small bar of compound with precision — simply rub the surface using controlled, consistent pressure.

Temperature management is often overlooked. Excessive heat can damage both your working surface and the polishing compound itself. Always monitor your working temperature, especially when dealing with sensitive materials like soft metals and wood.

Material compatibility is another frequent stumbling block. Not every oxide compound works perfectly for every surface. Aluminum responds differently than steel, and brass requires a different approach compared to stone. Research your specific material before selecting a polishing compound.

Technique trumps brute force. Many users mistakenly believe harder pressure produces a better edge. In reality, controlled, consistent motion creates the best possible edge. Let the compound’s unique properties do the hard work for you.

Elevate Your Polishing to New Heights With Advanced Abrasives

In the realm of precision and quality, every detail matters. With our Oxide Polishing products, you have the power to achieve impeccable results consistently. From powders or suspensions, get quality products engineered to deliver.

Harness the power of our oxide polishing solutions and experience the difference of Advanced Abrasives today. Let us assist you in achieving the proper metallographic preparation.