Application – Optical

Optical Polishing Abrasives for Precision Surface Finishing

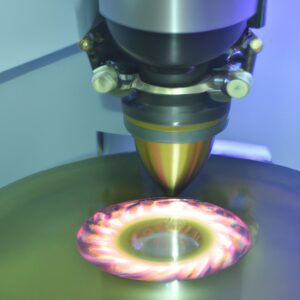

Optical components require a level of surface quality that exceeds standard finishing requirements. In optical applications, even minor surface irregularities can affect light transmission, image clarity, and system performance. Advanced Abrasives provides optical polishing abrasives engineered to support precision surface finishing for glass, optical fiber, and other sensitive materials used in optical systems.

Our optical polishing solutions are used across research, manufacturing, and production environments where controlled lapping and polishing are required to achieve consistent surface finishes. From early-stage grinding to final oxide polishing, our abrasives are designed to integrate smoothly into optical workflows while supporting repeatability, process control, and high-quality outcomes.

Understanding Optical Polishing and Surface Requirements

Optical polishing is a specialized surface finishing process focused on refining glass and related materials to achieve extremely smooth and uniform surfaces. Unlike conventional polishing, optical polishing must account for how light interacts with the surface, making surface roughness, subsurface damage, and material consistency critical factors.

In optical applications, polishing follows grinding and lapping steps that establish geometry and flatness. Each stage builds toward a final surface finish suitable for optical inspection and use. Advanced Abrasives supports every stage of this process by supplying abrasive materials designed for controlled material removal and predictable surface interaction.

Optical polishing is used in applications involving lenses, mirrors, prisms, windows, and optical fiber components. These parts are commonly used in imaging systems, laser assemblies, sensors, and communication technologies where surface integrity directly affects performance.

Abrasive Solutions for Optical Polishing Applications

Advanced Abrasives offers a range of abrasive products tailored for optical polishing applications. These products are selected based on material type, polishing stage, and target surface finish requirements.

Abrasive Powders and Slurries

Abrasive powders and slurries play a central role in optical polishing by providing controlled cutting action and consistent particle distribution. These materials are commonly used during fine polishing stages to refine surface texture and remove residual damage from prior steps.

Our optical polishing abrasives include oxide-based powders and slurries that support polishing of glass and related substrates. For select applications, diamond compounds and pastes support controlled polishing action on harder surfaces and tight tolerance features. Silicon dioxide abrasives are frequently used due to their compatibility with optical glass and their ability to deliver smooth, controlled finishes without aggressive cutting behavior.

Slurry formulations allow abrasives to be delivered evenly across the polishing surface, supporting consistent results and reducing variability across parts. These products are used in both manual and automated polishing systems where control and repeatability are essential.

Oxide Polishing for Optical Components

Oxide polishing is a critical step in optical surface finishing, particularly for glass and optical fiber components. Oxide abrasives are selected for their ability to polish without introducing excessive subsurface damage, which can interfere with optical performance.

Advanced Abrasives supplies oxide polishing materials designed to support high-clarity finishes on optical surfaces, including programs focused on precision glass finishing. These products are used to refine surface finish after lapping and fine grinding steps, helping achieve the smoothness required for optical inspection and use.

Oxide polishing is commonly applied in the final stages of optical component manufacturing. It supports the removal of fine scratches and helps produce surfaces suitable for high-magnification inspection and functional optical testing.

Lapping and Grinding in Optical Workflows

Before polishing can begin, optical components often undergo lapping and grinding to establish shape, flatness, and dimensional accuracy. Advanced Abrasives supports these steps by providing abrasive materials compatible with optical substrates.

Lapping processes use controlled abrasive action to correct surface geometry and prepare parts for polishing. Fine lapping helps minimize surface irregularities and creates a uniform starting point for subsequent polishing stages.

Grinding is typically used earlier in the process to remove material more aggressively. Abrasive materials used in grinding must balance cutting efficiency with surface protection to avoid introducing damage that is difficult to remove later. Our abrasives support gradual transitions from grinding to lapping and polishing, helping maintain surface integrity throughout the workflow.

Materials Supported in Optical Polishing Applications

Optical polishing abrasives must be compatible with a wide range of materials used in optical systems. Advanced Abrasives supplies products used to polish and finish:

- Optical glass used in lenses and windows

- Fiber and optical fiber components used in communication systems

- Carbide-based substrates used in specialized optical assemblies

- Silicon-based materials used in advanced optical and electronic applications

Each material responds differently to abrasive interaction. When harder substrates drive higher cutting demands, our superabrasive formulations support precision surface finishing with consistent results. Selecting the correct abrasive powder, slurry, or oxide polishing material helps control surface finish while reducing the risk of defects that affect optical performance.

Process Control and Consistency in Optical Polishing

Consistency is critical in optical polishing, especially in production environments where multiple components must meet identical surface finish standards. Advanced Abrasives focuses on supplying abrasive materials that support stable polishing behavior across runs.

Controlled particle size, reliable dispersion in slurry systems, and predictable abrasive action all contribute to consistent outcomes. These factors help reduce rework, limit variability, and support quality control requirements in optical manufacturing.

Optical polishing often involves long cycle times and close monitoring. Consistent abrasives help technicians maintain process control and achieve reliable results without unnecessary adjustments.

Optical Polishing for Optical Fiber Applications

Optical fiber components require careful surface preparation to support efficient signal transmission. Polishing optical fiber involves creating smooth end faces and surfaces that minimize signal loss and reflection.

Advanced Abrasives supplies polishing materials used in optical fiber preparation, including oxide abrasives and fine polishing slurries. These products support controlled material removal and smooth surface finishes that align with optical fiber performance requirements.

Fiber polishing processes often require precise control over pressure and abrasive interaction. Our optical polishing abrasives are designed to support these requirements while integrating into established fiber preparation workflows.

Integration With Polishing Equipment and Systems

Optical polishing abrasives from Advanced Abrasives are compatible with a wide range of polishing equipment and systems. These include flat lapping machines, precision polishing systems, and specialized optical finishing equipment.

Our products are used in laboratory environments, pilot production lines, and full-scale manufacturing operations. For optical parts that need specialized handling before polishing, flex fabrication supports prep steps that help polishing run cleaner and more consistently. This flexibility allows customers to use the same abrasive systems across different stages of development and production. Compatibility with common polishing tools and machines helps streamline optical finishing processes and simplifies material selection for engineering and production teams.

Supporting Research, Manufacturing, and Production Needs

Advanced Abrasives works with customers across research institutions, optical manufacturers, and technology companies. Our optical polishing abrasives support applications ranging from prototype development to high-volume production.

In research environments, consistent polishing supports accurate testing and evaluation of optical components. In manufacturing, reliable abrasives help maintain throughput and quality. Across all applications, our focus is on supplying materials that align with real-world optical polishing requirements.

Work With Advanced Abrasives for Optical Polishing Solutions

If your optical applications require controlled polishing, reliable surface finish results, and abrasive materials designed for precision work, Advanced Abrasives is ready to support your process. Our team works with customers to align abrasive selection with material type, polishing stage, and performance goals.

Reach out to Advanced Abrasives to discuss your optical polishing application, request technical guidance, or explore abrasive options designed to support high-quality optical surface finishing. We are ready to help you achieve consistent results and advance your optical manufacturing capabilities.