Lapping Film

Precision-Coated Abrasives for Superior Surface Finishing

Lapping film is a precision-coated abrasive that plays a vital role in manufacturing and finishing processes across numerous industries. Using lapping film can significantly improve surface finish quality, leading to higher product performance, reliability, and lifespan. High-quality lapping films allow your business to meet exact surface specifications required by high-tech products, components, and assemblies.

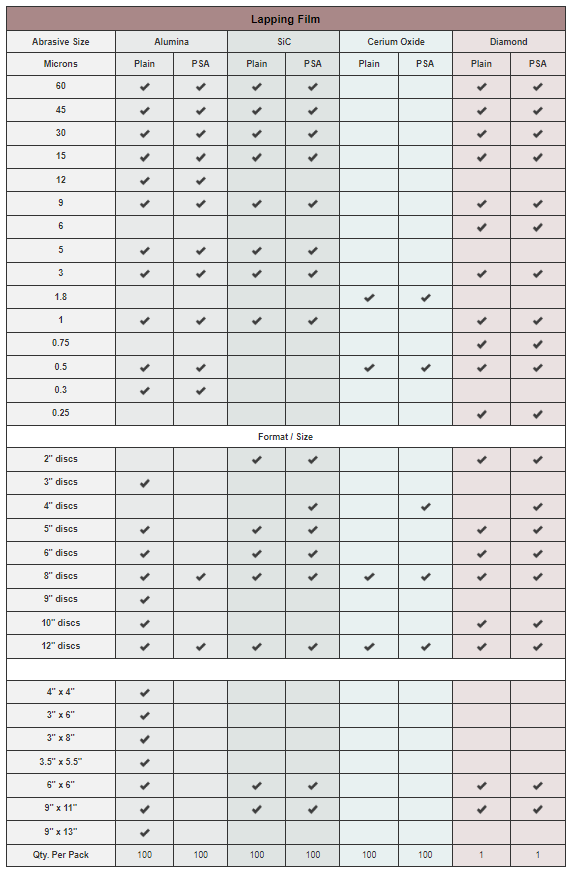

At Advanced Abrasives, we specialize in producing and supplying lapping films that meet the strictest manufacturing and measurement standards. Each film is engineered to deliver controlled cutting, uniform wear, and predictable surface roughness results. Our films are precision-coated using high-grade abrasive minerals such as diamond, aluminium oxide, silicon carbide, or cerium oxide. We manufacture them in various formats, including sheets, rolls, discs, and belts, suitable for both manual and CNC machining systems.

Our Lapping Film Capabilities

Our lapping films are particularly effective for precision micro-finishing operations, offering the consistency required in modern manufacturing environments. These films can be used for both dry and wet processes and integrate seamlessly into polishing, grinding, honing, and superfinishing systems.

At Advanced Abrasives, we support customers through every stage of their process, from abrasive selection and film specification to quality assurance and testing. Our technical specialists work with machinists, engineers, and quality managers to identify the best film type and micron rating for each application. We provide data-driven guidance to help customers achieve consistent geometry, waviness, and average roughness parameters across production runs.

Our Services Include:

- Custom abrasive coating: Precise distribution of abrasive grains using calibrated machinery to achieve uniform film coating thickness.

- Film conversion and sizing: Die-cutting and trimming to exact dimensions for machine tools, polishing heads, and sheet metal finishing systems.

- Performance testing and validation: Profilometer and root mean square surface measurements to verify film performance under controlled stress and friction conditions.

- Process optimization support: Consultation for integrating lapping films with CNC machining, electroplating, laser cutting, and other surface finishing processes.

- Supply chain consistency: Quick turnaround times, standardized quality documentation, and repeatable micron specifications.

Alumina-Coated Lapping Film

Alumina-coated lapping film provides durability and efficiency for achieving fine finishes on hard materials. This type of film incorporates aluminium oxide, combining hardness and cutting precision ideal for polishing metals, ceramics, and composite parts. The consistent abrasive grain distribution maintains predictable cutting rates and reduces waviness in the finished surface.

Applications include polishing stainless steel, carbon steel, and aluminium components used in mechanical assemblies, bearings, and cutting tool manufacturing. Our alumina-coated films support accurate parameter control, making them ideal for metallography, machine tool maintenance, and quality assurance testing environments.

SiC-Coated Lapping Film

Silicon carbide, or SiC-coated, lapping film is designed for aggressive material removal and high-quality surface finish. Silicon carbide is a sharper abrasive than alumina, providing rapid cutting action on materials like titanium, hardened steel, and glass. Its high hardness minimizes friction while improving adhesion of subsequent coatings such as electroplating, paint, or powder coating.

Our SiC-coated lapping films are available in multiple grit and micron sizes, providing machinists and toolmakers flexibility across different manufacturing processes, from rough lapping and grinding to fine superfinishing. These films are also used for surface preparation before welding, plating, and passivation.

Cerium Oxide-Coated Lapping Film

Cerium oxide-coated lapping film is developed for optical and high-clarity polishing applications. This abrasive chemical compound provides both mechanical and chemical action, efficiently removing micro-scratches and surface contamination. The film delivers mirror-quality finishes on optical fibers, lenses, and precision glass components used in laser systems, sensors, and medical instruments.

By combining controlled pH chemistry with uniform coating, our cerium oxide films offer unmatched clarity, a vital property for optics manufacturing and electronic component polishing. They are often used alongside diamond and colloidal silica slurries for multi-step polishing processes that demand sub-micron accuracy.

Diamond-Coated Lapping Film

Diamond-coated lapping film represents the highest level of abrasive technology. The diamond particles, securely bonded to the resin coating, deliver superior wear resistance and consistent removal rates. Because diamond is the hardest known material, these films perform exceptionally well on carbide, ceramics, hardened steels, and metal casting materials.

Diamond lapping films are critical in toolmaking, cutting tool sharpening, and high-precision machining, where dimensional stability and smoothness are essential. Machinists rely on these films to achieve uniform cutting-edge geometry and improved performance under high heat and stress. When measured under a profilometer, diamond films yield minimal root mean square surface variation, confirming their ability to meet demanding industrial specifications.

Advanced Abrasives: Supporting Every Stage of Your Process

We go beyond supplying film: we support the entire finishing process. Our experts help customers interpret surface roughness data, define polishing sequences, and select the correct abrasive progression for optimal results. From sheet metal deburring to laser engraving refinement, our abrasive lapping films integrate with modern equipment, including CNC machining centers, automated polishing heads, and 3D printing post-processing systems.

Our films are compatible with a variety of substrates and can be used before or after electroplating, powder coating, or paint application. They play a key role in producing surfaces that exhibit stable adhesion, low friction, and improved corrosion resistance. We also provide technical support for integrating films into automated polishing and measuring equipment to maintain tight tolerances and micron-level precision.

Use Our Lapping Films Across Your Industry

Advanced Abrasives’ lapping films are used across industries that require precise, consistent, and measurable surface finishing. These include:

- Metal fabrication, CNC machining, and mechanical component manufacturing

- Optics, laser cutting, and laser engraving

- Aerospace and defense machining of carbon steel, stainless steel, and titanium

- Automotive machining and superfinishing of engine components and bearings

- Electronics, sensor, and semiconductor device polishing

- Tool and die manufacturing, cutting tool sharpening, and carbide coating preparation

- 3D printing post-processing, surface smoothing, and resin finishing

- Metallography and materials testing laboratories

- Medical device and optics polishing

The versatility of our films helps manufacturers achieve exacting surface roughness and waviness parameters while reducing vibration and improving wear performance across metal, ceramic, and plastic materials.

Get Lapping Film Today from Advanced Abrasives

The pursuit of accuracy in modern manufacturing demands tools and materials that deliver measurable performance. Advanced Abrasives stands at the forefront of surface finishing technology, providing state-of-the-art lapping films designed for precision, reliability, and repeatability. With our range of alumina, SiC, cerium oxide, and diamond-coated lapping films, you can achieve the exact surface finish for your specifications quickly, efficiently, and consistently.

Choose Advanced Abrasives for your lapping film needs, or explore our selection of lapping pitch and other lapping/polishing abrasives to further enhance your production capabilities. Our experts are ready to help you select the right abrasive film to enhance your machining, polishing, and lapping processes today.