Diamond Slurries & Suspensions

Engineered for Precision Polishing and Lapping

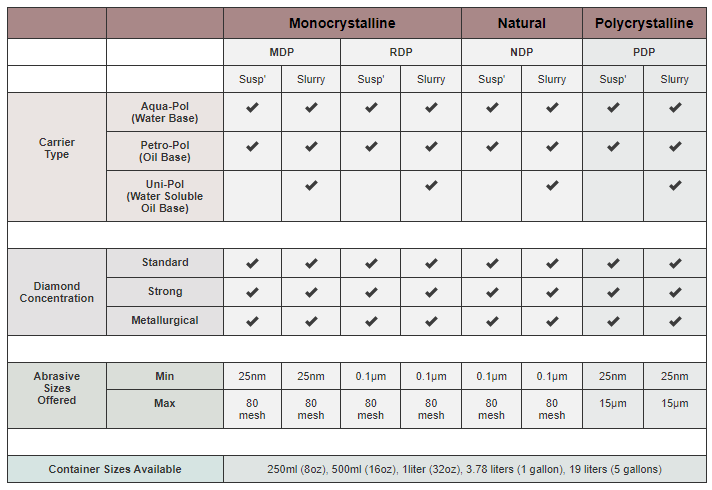

Advanced Abrasives offers an extensive range of diamond superabrasive slurries and suspensions. All of our formulations are available in multiple standard abrasive sizes and types, with your choice of three concentrations of diamond particles in our proprietary Aqua-Pol, Petro-Pol, and Uni-Pol carriers.

- Aqua-Pol slurries and suspensions are water-based and water-soluble for simple cleanup, ideal for processes that require minimal residue.

- Petro-Pol slurries are oil-based and formulated for applications where water cannot be tolerated due to potential corrosion or contamination.

- Uni-Pol suspensions combine the performance of an oil-based finish with the easy cleanup of a water/detergent system.

Each formulation is designed to precisely control particle size, viscosity, and dispersion, maintaining a stable abrasive suspension even during high-pressure polishing and lapping. We offer three concentration levels — standard, strong, and metallurgical — available in container sizes from 250 ml (8 oz.) to 19 liters (5 gallons).

A broad selection of monocrystalline and polycrystalline diamond superabrasive products are available in various concentrations and carriers as slurries or suspensions.

Our Diamond Slurry & Suspension Services

At Advanced Abrasives, we do more than manufacture superabrasive fluids; we provide comprehensive support for every step of your polishing, grinding, and lapping process. Our diamond suspension and slurry services are built around precision manufacturing, calibration, and verification.

What We Offer

- Custom Blending: Tailored diamond suspension formulations based on required particle size, carrier system, and concentration to meet specific MRR and surface finish targets.

- Analytical Testing: Every batch is verified for particle dispersion uniformity, viscosity, and fluid stability using advanced filtration and microscope-based inspection.

- Technical Consultation: Our experts assist in selecting the correct diamond type — monocrystalline, polycrystalline, or synthetic diamond — for your metal, ceramic, or semiconductor application.

- Process Integration: We collaborate with engineers to match suspension behavior to machine settings, pad materials, and polishing system pressure.

- Product Data & Documentation: Each product is supplied with a complete safety data sheet and calibration data to support your internal quality control processes.

These services allow clients to achieve repeatable results across metal, glass, and composite surfaces while maintaining high efficiency and consistent performance in demanding environments.

Diamond Suspension Polishing

Our diamond suspension polishing materials produce consistent, uniform surface finishes for industries ranging from optics to semiconductor manufacturing. Monocrystalline suspensions, composed of single crystal diamond particles, are typically water-based and best suited for fine finishing on glass, sapphire, and plastics.

For harder materials such as ceramics, nickel alloys, and steel, we recommend polycrystalline suspensions. The fused microcrystal structure of polycrystalline diamonds delivers enhanced hardness, reduced friability, and greater resistance to deformation during high-pressure polishing.

By adjusting viscosity, grain size, and concentration, we help manufacturers refine wafers, metallographic samples, and precision optical components to meet exact surface roughness specifications.

Diamond Slurry Polishing and Lapping

Our diamond slurry polishing and lapping products provide advanced lubrication and consistent particle dispersion. The balanced liquid-to-powder mixture prevents settling, promoting even distribution of abrasive grains throughout the process.

Performance Benefits

- High material removal rate (MRR) without compromising surface integrity

- Controlled polishing for low surface roughness and minimal subsurface damage

- Stable dispersion of diamond particles during continuous machine operation

- Compatibility with various tools, machines, and metallographic systems

- Superior stock removal for stainless steel, carbide, and other ferrous metals

We produce diamond slurries for both high-volume manufacturing and laboratory applications. These formulations are trusted in aerospace, valve manufacturing, and semiconductor wafer finishing, where precision and repeatability are critical.

Advantages of Polycrystalline Diamond Suspension

Polycrystalline diamond suspensions provide a unique advantage in fine surface preparation. Each particle consists of numerous fused diamond microcrystals, enhancing their cutting efficiency and maintaining sharpness over extended use.

Key Advantages

- Higher cutting speed and improved MRR under pressure

- Reduced deformation and smoother surface profiles

- Greater durability and particle retention in resin-bond tools

- Better performance during polishing of ceramic, carbide, and metal components

- Stable viscosity and minimal contamination for consistent results

These suspensions are designed to perform in demanding polishing systems, including grinding machines, wafer preparation lines, and metallographic laboratories.

Diamond Slurry for Precision Finishing

Diamond slurries play a central role in achieving high-quality surface finishes in advanced manufacturing. By suspending precisely graded abrasive particles in a stable liquid carrier, they create a balanced polishing fluid that controls friction and heat across the contact area.

Properly formulated slurries produce predictable results on a variety of materials, including silicon, nitride, and composite coatings. With the right concentrate and carrier system, surface roughness values can reach below one nanometer Ra. These results are confirmed through profilometer readings and optical microscope analysis, allowing users to validate data and maintain tight process control.

Each slurry formulation undergoes precision milling and filtration to prevent contamination and maintain consistent grain size distribution, providing reliable dispersion and performance in every application.

Selecting the Right Diamond Suspension or Slurry

Choosing the correct diamond suspension or slurry depends on several variables:

- Particle size: Coarser grades remove material quickly, while fine micron sizes provide ultra-smooth finishes.

- Material type: Harder materials like ceramics, carbide, and sapphire may require higher diamond concentrations, while plastics and softer metals benefit from lower levels.

- Polishing system: High-viscosity slurries perform well in mechanical lapping systems, while thinner emulsions are preferred for precision polishing machines and metallographic setups.

- Carrier preference: Water, oil, or hybrid fluid systems can be selected based on your process needs and corrosion control requirements.

Our specialists evaluate your setup, review technical information, and recommend optimal formulations to achieve desired stock removal and finish parameters.

Get Your Diamond Slurry or Suspension from Advanced Abrasives

Advanced Abrasives delivers precision-engineered diamond suspensions and slurries that meet the strict demands of modern manufacturing. Our expertise in abrasive fluid behavior, particle calibration, and chemical vapor deposition diamond technology positions us as a trusted partner for industries that rely on accuracy, stability, and performance.

From glass polishing and semiconductor wafer preparation to aerospace and metallography, our diamond suspension products drive innovation and reliability. Contact our team today for technical data, quotes, or guidance on the best slurry, suspension, compound, extension, or paste for your specific material, machine, and surface finish requirements.