Diamond Compounds & Paste

Premium Diamond Compounds for Professional Polishing and Lapping

Advanced Abrasives diamond compounds (pastes) are formulated using tightly graded diamond powders and proprietary carriers for fast cutting action, excellent surface finish, and easy cleanup. Each diamond compound is manufactured under strict particle size control, guaranteeing consistent quality and predictable polishing performance.

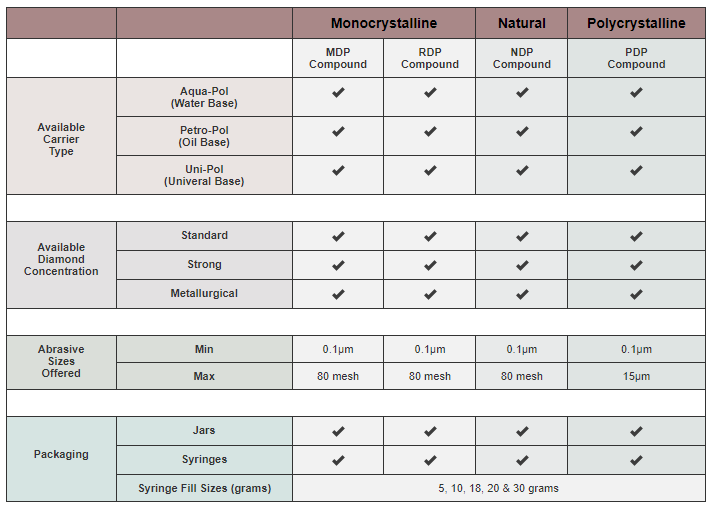

We produce both natural and synthetic diamond formulations, available as Natural Diamond (NDP), Synthetic Monocrystalline Diamond (MDP and RDP), and Polycrystalline Diamond (PDP). Each option is offered in multiple concentration levels and carrier types to fit specific polishing and lapping requirements.

Our diamond compounds are color-coded by particle size to simplify identification during progressive polishing stages and are packaged in jars or syringes for convenience. These versatile materials are ideal for industries working with molds, gemstones, metal tools, and lapidary projects that demand precision and repeatable results.

What is Diamond Compound Used For?

Diamond compounds are remarkable tools for smoothing and polishing materials of any hardness. From metals to plastics, it can be used to create glossy finishes by virtue of the hardest mineral available today. Diamond compounds help individuals in various industries save cash and ensure a smooth and well-polished surface. They’re used for a variety of needs, including:

- Polishing and grinding jewelry or gems and removing scratches and damage.

- Grinding compound used for tungsten carbide blades, optical molds, injection molds, etc.

- Optical lenses, quartz wafers, sapphire, and semiconductors.

- Polishing and grinding magnetic minerals, ceramics, and cemented carbide.

- The diamond polishing compound is also used to finalize medical or dental equipment (i.e., dentures).

Diamond Compound & Diamond Paste Services

Advanced Abrasives provides a complete line of services to help manufacturers and technicians achieve optimal results with our diamond lapping and polishing compounds. From product formulation to application consultation, our team supports customers in every phase of their surface finishing process.

Our Services Include:

- Custom Formulation & Concentration Adjustment: We blend each compound to your specified abrasive particle size, carrier composition, and concentration level for uniform removal rates and reliable surface finish control.

- Material Compatibility Consultation: Our experts recommend the correct compound for your workpiece, from polishing molds and dies to processing gemstones, ceramics, and hard metals.

- Process Optimization: We provide detailed data on cutting rates, viscosity, and polishing behavior, helping clients select the correct slurry or diamond paste polish for their unique setup.

- Product Selection Support: We help clients choose between monocrystalline, polycrystalline, and natural diamond pastes, as well as the correct carrier base — water, oil, or universal.

- Performance Testing: Each batch undergoes controlled testing on lapping plates and polishing tools to confirm the expected surface roughness and reflectivity.

Our compounds can be used manually or with mechanical polishing tools, CNC lapping machines, or automated finishing systems. We also assist clients with integrating diamond stropping compound applications for fine tool edges and maintenance operations.

Diamond Paste Polish and Compound Applications

Diamond Paste Polish

Advanced Abrasives diamond paste polish is a water-based compound containing sub-micron monocrystalline diamond powder and proprietary lubricants. Designed for polishing and lapping metals, ceramics, plastics, and composites, it offers an ideal balance between cutting action and high-gloss finishing. Available in a range of micron sizes, this product supports precise surface finishing for molds, dies, and optical components.

Use our diamond paste polish for:

- Manual or machine polishing of molds and dies

- Lapping and surface smoothing of hard metals

- Polishing coatings and restoring adhesion surfaces

- Stropping and sharpening of precision tools and blades

- Applications requiring white diamond polishing compound for fine finishes

Each formulation provides consistent performance and easy cleanup, making it ideal for both industrial and lapidary applications.

Advanced Diamond Polishing Compounds

Our diamond polishing compound line is available in multiple viscosity and concentration levels, optimized for your specific polishing parameters. The compounds are compatible with a wide range of surfaces, including gemstone materials, steel molds, and silicon wafers.

Performance Benefits

- Fast, controlled cutting for uniform surface finish results

- Predictable removal rates during each polishing stage

- Compatibility with oil or water-based systems

- Excellent dispersion for use in slurries, pastes, or suspensions

- Reduced heat buildup for extended tool life and consistent polishing performance

Each diamond compound product undergoes rigorous testing to maintain uniform distribution of diamonds, providing superior performance under both high-speed and precision lapping conditions.

Diamond Polishing Compound for All Applications

Diamond polishing compounds represent the highest standard of abrasive materials in modern manufacturing. Their combination of extreme hardness, thermal conductivity, and chemical stability enables them to perform in demanding polishing and lapping operations.

These materials are essential for refining molds, gemstones, and optical surfaces, offering micron-level precision and smoothness. The superior behavior of diamond paste and diamond lapping compound allows for consistent adhesion, reliable repeatability, and professional-grade surface finish results across all industries.

Applications include:

- Precision optics: Producing ultra-smooth surfaces on glass, sapphire, and crystal components for lenses and prisms.

- Semiconductors: Preparing atomically flat silicon wafers using diamond polishing paste for microchip production.

- Automotive and aerospace: Polishing hard alloys, ceramics, and composites for improved wear resistance and lower friction.

- Gemstone and jewelry: Enhancing brilliance and reflection through multi-step polishing using white diamond polishing compound.

- Medical and dental tools: Achieving smooth, sterile finishes on implants and instruments through controlled polishing processes.

Our data-driven approach allows customers to achieve repeatable surface measurements, providing the accuracy required for research, development, and large-scale manufacturing.

How Diamond Compounds Advance Materials Science

Diamond polishing pastes contribute significantly to materials science and research by creating ultra-smooth surfaces for high-resolution microscopy, spectroscopy, and surface analysis. In semiconductor and optics laboratories, our compounds are used to achieve atomic-level flatness, enabling advanced research in electronics and quantum technology.

Because diamond is chemically inert, it maintains the purity of materials during experiments and production. The consistent cutting action and uniform surface finish make our products essential for labs focused on nanoscale surface modification and adhesion testing.

Secure Your Diamond Compound or Paste from Advanced Abrasives

Advanced Abrasives offers professional-grade products and technical support that continue to set industry benchmarks for precision and consistency. From standard diamond paste polish to custom synthetic diamond suspensions, we supply tailored solutions for every polishing requirement.

Why Partner with Us:

- Expert guidance on choosing the correct diamond compound concentration and carrier

- Access to detailed process data and surface behavior reports

- Large selection of diamond polishing compounds and slurry formulations

- Support for mold finishing, gemstone processing, and industrial polishing systems

- Reliable global delivery supported by our technical and marketing teams

Pair your diamond paste with our abrasive lapping products, or explore our range of diamond slurries and suspensions. Each product is designed to perform with the same level of precision and reliability that defines the Advanced Abrasives name.

Contact Advanced Abrasives Today

For a premium polish, reliable lapping performance, and measurable surface finish results, contact Advanced Abrasives today. Speak with our technical experts to discuss which diamond compound, diamond paste, or slurry system best fits your requirements.

Our diamond lapping compounds are the choice of professionals worldwide, trusted for their precision, consistency, and unmatched polishing efficiency. Request a quote, review product specifications, or talk to our specialists to learn how our advanced abrasive technologies, including diamond suspensions, compounds, and extenders, as well as our superabrasive formulations, can enhance your process today.