Custom Tailored Powders

Custom Tailored Superabrasive Powder Solutions

Advanced Abrasives Corporation consults directly with you to design and manufacture custom-tailored superabrasive powder solutions to meet your exact application requirements.

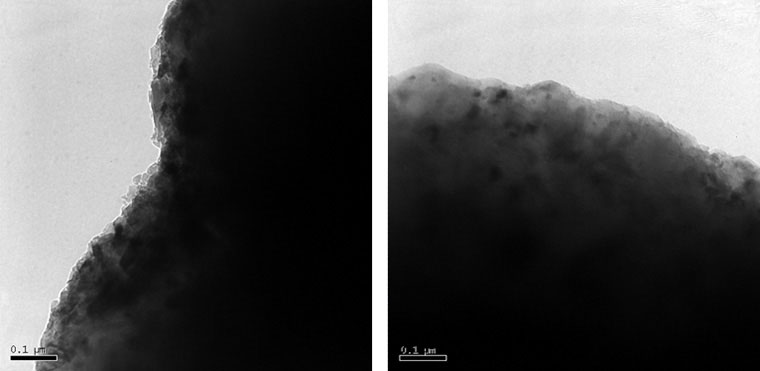

As an independently owned and operated micronizer of superabrasive powder products, our unique advantage is that we control the crystal type, crystal shape, crystal cleanliness, and size distribution from start to finish. We have designed and developed unique milling technologies that allow us to tailor shape a product to a customer’s specific needs regarding bond retention and/or cutting, polishing, or grinding properties. We have developed proprietary methods of applying nano-size diamond crystallites to micron-size diamond particles for special applications. The cleaning process employed is superior to those used for many superabrasive products from other suppliers, ensuring the best possible cleanliness of diamond powder from Advanced Abrasives Corporation.

Every carat is put through a stringent cleaning process developed around our customers’ requirements. High surface purity is a must for many of our customers’ high-end value products because of the enhanced bond characteristics it produces. We can develop and supply coated, compounded, or stratified blends unique to your application needs. With competitive pricing and millions of carats in stock, Advanced Abrasives is an excellent choice to partner with your company. No order is too large or too small, and private labeling is always an option.

Let us work with your Applications Engineers or R&D Department to develop next-generation products that will help put your products ahead of the competition. Call us with your request, and we will tailor a product and process that is custom-made for your application.

Our Nano Diamond Coated Micron Powder line provides a product that greatly enhances the subsequent polycrystalline network by increasing diamond-to-diamond bonding during the pressing/sintering process. The proprietary coating process deposits a uniform layer of nanometer-sized diamonds on each individual particle of the primary diamond product. Our micron line of diamond powders can be uniformly coated with nanodiamonds in sizes ranging from 100 nm all the way down to 25 nm. The nanometer-sized diamond is made from the parent crystal of the base material so can retain the original high-level purity. Our process coats only the particle, thereby reducing the amount of free nanometer diamond that could potentially result in a non-homogeneous blend of diamond/catalyst. New coatings, such as high-purity nano-size catalyst coatings, are being developed on a continuous basis, and we would be pleased to discuss developing a coating specific to your application needs.

Industry Applications for Our Custom Tailored Superabrasive Powder Solutions

Our custom-tailored superabrasive powder solutions are not just a product; they’re a game changer across various industries. Designed to meet the unique demands of numerous industries, these solutions deliver unparalleled performance for various needs.

Automotive Industry

In the automotive industry, our superabrasive powders play a critical role in the manufacturing and finishing processes of various components. From enhancing the surface finish of engine parts to improving the hardness of cutting tools, our solutions provide the necessary edge.

Aerospace & Defense

The aerospace and defense industry requires materials that can withstand extreme conditions. Our superabrasive powders are used in the manufacturing of high-performance components, ensuring durability and longevity even in the harshest environments.

Electronics & Semiconductors

In the fast-paced electronics and semiconductor industry, our superabrasive powders contribute to the production of components with precise dimensions and superior surface finishes. These properties are crucial in the manufacturing of semiconductors, integrated circuits, and other microelectronics.

Oil & Gas Industry

Our superabrasive powders are extensively used in the oil and gas industry for drilling and exploration activities. The unmatched hardness and durability of our solutions help create drilling tools that can easily penetrate even the toughest rock formations.

Medical Industry

In the medical industry, our superabrasive powders are used in the manufacturing of medical devices and instruments. The powders provide the necessary hardness and wear resistance, ensuring the longevity and reliability of these critical tools.

Construction Industry

In the construction industry, our superabrasive powders are used in the production of cutting and drilling tools. These tools are designed to easily cut through hard materials such as concrete and steel, making construction processes more efficient.

Quality Assurance and Compliance in Our Custom Superabrasive Powders

Quality assurance is at the heart of our custom-tailored superabrasive powder solutions. Advanced Abrasives Corporation is committed to unwavering quality, and we’ve instituted robust processes to ensure each batch of powder meets the highest standards. We employ rigorous testing methodologies in our advanced laboratories, examining critical parameters such as particle size distribution, hardness, and purity.

Our production processes are meticulously controlled to guarantee consistency across all batches. Furthermore, we adhere strictly to ISO 9001:2015 certification and other industry standards, ensuring our products meet global quality management benchmarks. We also believe in continuous improvement, regularly updating our QA procedures and investing in cutting-edge testing equipment. Trust us to deliver superabrasive powder solutions that consistently exceed expectations.

Take Advantage of Our Nano Diamond Coated Micron Powder Line

Our Nano Diamond Coated Micron Powder is a revolutionary product that brings together the world of superabrasives and nanotechnology. This unique combination offers a host of benefits that can significantly enhance your operations, regardless of your industry.

Superior Performance

The nano diamond coating significantly enhances the performance of the micron powder. It offers superior hardness, thermal conductivity, and wear resistance, making it ideal for demanding applications.

Enhanced Bonding Strength

The nano diamond coating improves the bonding strength between the diamond particles and the bond, resulting in tools with longer life and better performance. This means less frequent tool replacement and more cost-effective operations.

Improved Surface Finish

Our Nano Diamond Coated Micron Powder delivers an excellent surface finish thanks to its ultra-fine particle size. It ensures precision and accuracy in applications requiring high surface integrity.

Versatility

The unique properties of our Nano Diamond Coated Micron Powder make it suitable for a variety of applications, including grinding, cutting, polishing, and more. Whether you’re in the automotive, aerospace, electronics, or any other industry, this product can revolutionize your manufacturing processes.

Custom Tailored Superabrasives for Grinding Wheels

We specialize in crafting superabrasive powders that revolutionize grinding wheel performance. Our expertise lies in developing custom solutions for the most demanding applications. This includes cubic boron nitride (CBN) and diamond crystals that outperform conventional abrasives by leaps and bounds. These aren’t your run-of-the-mill grinding materials; they are engineered to tackle the toughest jobs with precision and efficiency. When you’re grinding hardened steels or working with materials that push the limits of conventional abrasives, our superabrasives step up to the plate.

We provide solutions that boost your productivity and cut costs. By fine-tuning the particle size, shape, and composition of our CBN powders, we create grinding wheels that cut faster, last longer, and maintain their shape better than anything else on the market. It’s not just about grinding – it’s about grinding smarter.

Prioritize Thermal Stability and Thermal Conductivity With Custom Superabrasives

Heat is the biggest negative factor for efficient grinding. Our custom superabrasives are designed with thermal stability and conductivity at the forefront, which is the key to unlocking peak performance in high-temperature applications. When you’re pushing the limits of what’s possible in grinding, heat buildup can be your worst enemy. Our CBN powders shine as we engineer these powerhouses to withstand extreme temperatures. They conduct heat away from the grinding zone, which means you can push your grinding processes harder and faster without worrying about thermal damage to your workpiece. Advanced Abrasives is providing a custom solution to one of the biggest challenges in precision grinding, optimizing thermal properties, and opening doors to applications that were once thought impossible.

Add a Copper or Nickel Coating to Your Superabrasive Solutions

Take your superabrasives to the next level with our coating options. We offer copper and nickel coatings that transform good superabrasives into great ones. Why bother with coatings? It’s simple: they enhance retention, improve heat dissipation, and can even boost the cutting action of your CBN powders and diamond crystals. A layer of copper or nickel acts like a high-tech glue, keeping your superabrasives firmly in place during the most demanding grinding operations.

These coatings are leaders in thermal conductivity. They whisk heat away from the grinding zone, reducing the risk of thermal damage and allowing for more aggressive grinding parameters. And best of all, by tweaking the coating thickness and composition, we can fine-tune the cutting characteristics of your superabrasives. Want a more aggressive cut for roughing operations? Need a smoother finish for those final passes? No problem. We add another dimension of control to your grinding process.

Get Your Custom Superabrasive Powder Solution

Advanced Abrasives Corporation’s custom-tailored superabrasive powder solutions are designed to meet your unique needs and deliver superior performance. They offer unparalleled hardness, consistency, and quality, ensuring they stand up to even the most demanding applications. But don’t just take our word for it. Experience the difference for yourself. Contact us today to learn more about our custom-tailored powders, and let us help you enhance your operations, improve productivity, and achieve outstanding results. Or explore our premium sintering feedstock or Cubic Boron Nitride (cBN).