cBN (Cubic Boron Nitride)

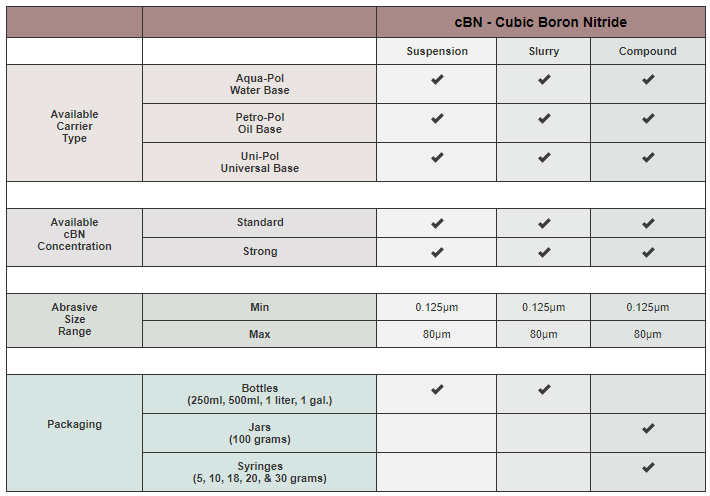

Our high-quality cBN cubic boron nitride powder is combined with our proprietary water, oil, or universal carrier bases to provide cBN Aqua-Pol, cBN Petro-Pol, and cBN Uni-Pol slurries, suspensions, and compounds available in abrasive sizes ranging from 0.125µm to 80 mesh.

cBN Slurries

Cubic Boron Nitride (cBN) slurries are high-performance solutions that combine microscopic cBN particles with carefully selected carrier fluids, creating a potent mixture for superior material removal and surface finishing. Our cBN slurries excel in applications demanding accuracy and efficiency, particularly in hard material processing. The unique properties of cBN, including its extreme hardness second only to diamond, thermal stability, and chemical inertness, make these slurries indispensable in industries. By using our cBN slurries, manufacturers achieve exceptional surface quality, tight tolerances, and extended tool life, revolutionizing their production processes and setting new standards in product quality.

cBN Suspensions

cBN suspensions elevate abrasive technology to new heights, offering stability and performance in demanding applications. These advanced formulations keep cBN particles uniformly dispersed, providing consistent results throughout extended use. Our cBN suspensions are engineered for optimal particle distribution, preventing settling and agglomeration that can compromise abrasive effectiveness. This stability translates to superior control over material removal rates and surface finish quality, which is critical in high-precision manufacturing environments. The versatility of our cBN suspensions allows for their application in various methods, including spray systems and automated polishing equipment, enhancing productivity and reducing waste. Improve process reliability, reduce downtime, and achieve previously unattainable levels of surface perfection.

cBN Compounds

cBN compounds offer a solid-form alternative that combines the superior properties of cBN with carefully selected binding agents. These innovative products deliver wonderful performance in applications where traditional abrasives fall short. Our cBN compounds are formulated to provide controlled abrasion, making them ideal for precision lapping, polishing, and superfinishing operations on hard and super-hard materials. The unique composition of these compounds allows for gradual breakdown during use, continuously exposing fresh cBN particles and maintaining optimal cutting throughout the process. This self-sharpening characteristic results in consistent performance, reduced processing times, and superior surface finishes. Manufacturers can tackle the most challenging materials with confidence, achieving fantastic results in terms of dimensional accuracy and surface quality.

The Versatility of Cubic Boron Nitride

Cubic Boron Nitride (cBN) is a synthetic crystalline material second only to diamond in hardness. It is renowned for its durability, thermal stability, and chemical inertness, making it a highly desirable superabrasive for industrial applications.

cBN’s hardness is surpassed only by diamond, making it incredibly resistant to wear and tear. This makes it ideal for tools and equipment expected to withstand harsh conditions and heavy usage. Additionally, cBN maintains its integrity under high temperatures, particularly in an environment with iron or nickel. This makes it highly suitable for machining ferrous materials where diamond would oxidize and degrade.

It also provides resistance to chemical interaction with ferrous materials at high temperatures, providing a clean cut without the risk of reaction or adhesion. Get a smooth, high-quality finish in machining applications.

Incorporating cubic boron nitride into your processes can significantly enhance efficiency, productivity, and product quality. Discover the power of cBN for your operation with Advanced Abrasives.

cBN Applications and Industry Uses

Cubic boron nitride (cBN) powder is highly valued across various industries due to its exceptional hardness, thermal stability, and chemical inertness. Here’s a list of some of the key applications and industry uses of cubic boron nitride powder:

- Grinding Ferrous Metals: cBN abrasive tools deliver excellent grinding performance, especially for high-hardness, tough materials.

- Superabrasive Grinding Wheels: cBN grinding wheels have unique advantages in grinding materials that are difficult to cut due to their high strength and hardness.

- Dicing Blades: cBN is used in the production of dicing blades, which are used for cutting or slotting semiconductor wafers, silicon, glass, ceramic, etc.

- Polishing and Lapping Applications: Micron-sized cBN powders are used for polishing and lapping applications, improving the surface integrity of ferrous materials.

- Abrasive Machining Processes: cBN is an integral component in industrial abrasive machining processes like grinding and honing.

- Grinding Technical Blades: Abrasive tools made of cBN grains and vitrified bonds are widely used for shaping technical blades.

- Fine Machining Applications: cBN powder is used in fine machining applications, and it’s also suitable for manufacturing Polycrystalline Cubic Boron Nitride (PcBN) and abrasive paste.

The Advantages of Cubic Boron Nitride

With its unique properties, cBN powder is a game-changer for industries requiring high-performance abrasives and cutting tools. Some of the key advantages of incorporating cBN powder into your operations include:

Superior Hardness

cBN powder boasts a level of hardness second only to diamond. This makes it incredibly resistant to wear and tear, extending the lifespan of tools and equipment.

Exceptional Thermal Stability

Unlike diamond, cBN maintains its integrity under high temperatures, especially in environments where iron or nickel is present. This thermal stability makes it ideal for machining ferrous materials where diamond would oxidize and degrade.

Chemical Inertness

cBN powder’s chemical resistance is unmatched. It ensures a clean cut without the risk of reaction or adhesion when interacting with ferrous materials at high temperatures. This results in a smoother, higher-quality finish in machining applications.

Versatile Applications

Thanks to these qualities, cBN powder is widely used in grinding wheels, cutting tools, coatings, and other high-performance applications. Whether you’re hard machining, grinding hardened steels, or finishing high-temperature alloys, cBN can significantly enhance efficiency, productivity, and product quality.

Improved Efficiency

Using cBN powder in your tools can lead to faster cutting and grinding speeds, reducing downtime and increasing productivity. Its durability also means less frequent tool changes, further boosting operational efficiency.

How to Select the Right Product for Every Application

When selecting a cBN solution, consider factors like the hardness of the material you’re working with, the desired surface finish, and the specific requirements of your manufacturing process. For harder materials like high-speed steel or super alloys, our higher concentration cBN compounds offer superior cutting power. In contrast, for more delicate operations or softer materials, our finer grit suspensions provide excellent surface finishing capabilities. We’re committed to helping you find the perfect match for your unique challenges, leveraging our expertise in both superabrasive and conventional abrasive technologies to guide you toward the most effective solution.

Tips for Maximizing Efficiency and Optimum Usage of Our Cubic Boron Nitride Compounds

To get the most out of our cBN compounds, follow best practices in application and maintenance. First, always shake or stir the product thoroughly before use to evenly distribute the cBN particles. This step is crucial for maintaining consistent performance throughout your operation. When applying the compound, use the recommended amount for your specific tool and workpiece – overuse can lead to waste and potential clogging, while underuse may result in suboptimal cutting or polishing. Regular cleaning of your tools and work surfaces is vital to prevent build-up and maintain peak efficiency. For wet applications, maintain proper fluid levels and filtration to extend the life of the abrasive material. Monitor your process closely and adjust parameters like speed, pressure, and feed rate as needed to optimize results.

Following these guidelines and staying attentive to your specific process requirements helps maximize the efficiency of our cBN compounds and achieve superior outcomes in your manufacturing process. Speak with us today for further insight.

When to Use Diamond and When to Use cBN

Deciding between diamond and cubic boron nitride abrasives depends on several factors, including the workpiece material, desired finish, and specific application requirements. Diamond, the hardest known natural material, excels in applications involving non-ferrous metals, ceramics, and composites. It’s particularly effective for grinding and polishing materials like tungsten carbide, glass, and stone. Our highest-quality diamond particles, subjected to closely controlled grading, offer unparalleled performance in these areas.

On the other hand, cBN shines when working with ferrous materials like hardened steels and cast irons. It maintains its cutting edge at high temperatures, making it ideal for high-speed machining operations where diamond might graphitize. cBN also exhibits excellent chemical stability when in contact with iron, nickel, and cobalt, outperforming diamond in these scenarios. For applications involving heat-sensitive materials or where thermal damage is a concern, cBN’s superior thermal conductivity makes it the preferred choice. No matter what, you must carefully consider these factors, and we can help you select the most appropriate abrasive for your specific needs.

Secure Cubic Boron Nitride for Your Industry Applications Today

Experience the power of Cubic Boron Nitride (cBN) in your operations today. cBN is the key to unlocking higher productivity, efficiency, and quality in your manufacturing processes. Harness the transformative potential of cBN powder and take a bold step forward in your industry.