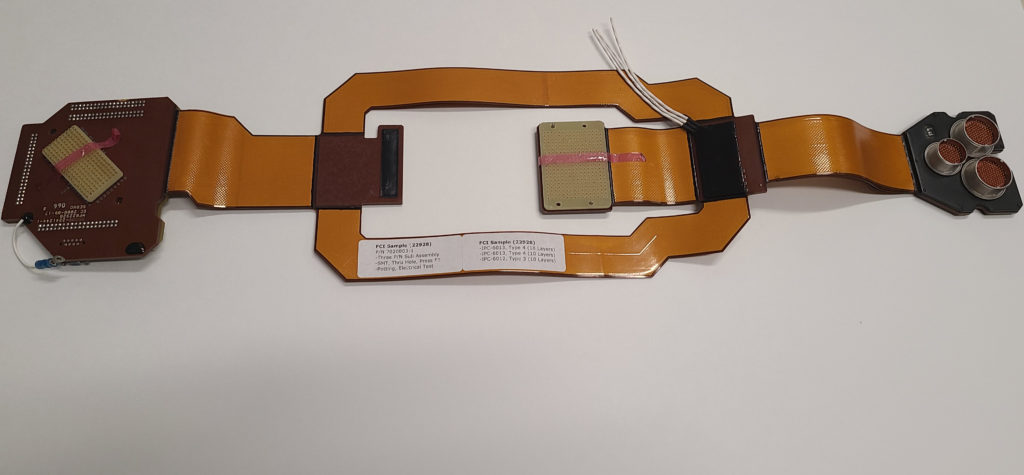

Flex Circuit Assembly

Complex flexible circuits require a meticulous and tightly-controlled assembly process that is uncompromising in the quality and performance it delivers. Flexible Circuits, Inc. brings intelligent turnkey solutions that your team can depend on. Our talented value-add team utilizes a combination of automated equipment, specialized fixturing, and the expertise of our highly-trained IPC-610 and J-STD certified operators to deliver top-quality flex circuit assemblies to you within our state-of-the-art value-add facility.

WE CAN DO IT ALL — EVEN PRINTED CIRCUIT BOARD ASSEMBLY

Every step of the flex fabrication process, from the initial design to the final assembly, is performed in-house at Flexible Circuits, Inc. Unlike other vendors and manufacturers, we take the time to learn your business inside and out so that we can develop a dynamic flex circuit that operates as intended from the very first use. Our team of expert engineers utilizes exotic, high-tech materials and state-of-the-art equipment to produce only the finest quality flexible circuit boards that deliver high performance every single time. We help you perfect your current applications and technology, so you can focus on the future.

Whether you’re looking for flex or rigid-flex circuits, single-sided or multi-layered printed circuit boards, Flexible Circuits, Inc. is your one-stop-shop for custom-made products. Contact us today to get started.

Connectors

Flexible Circuits, Inc. offers a range of solutions to maximize circuit performance. We have developed some of the highest-quality flex circuit board connectors to meet the challenges of modern flex circuit designs.

Flex Circuit Assembly Process FAQs

There are so many idiosyncrasies when working with flexible circuits. Each one can spell disaster if not properly handled. Flexible circuits have special and specific thermal and handling requirements due to the specialized material used in the manufacturing process. Very specific thermal profiles and specialized fixturing techniques are required throughout the entire assembly process. Most flexible circuit applications utilize multiple different thermal profiles and fixturing methods as it passes through assembly.

Unless you truly understand the properties of each material and have a high level of expertise with handling flexible circuit applications, results can be disastrous. This will lead to high-fallout/low-yield at a time when the cost of the product is at its highest — finished flexible circuits with expensive connectors. This also results in dramatically extending the cycle time as the client has to wait through another full manufacturing cycle as well as the added time involved with long connect lead times. Most importantly, the wrong supplier can deliver products that fail after delivery and in the field.

Yes! Custom turnkey solutions ensure that the flexible circuits are designed and assembled with your application in mind. You get better performance, better speed, and better results. Plus, turnkey solutions guarantee that your flexible circuits work the first time, every time.

"*" indicates required fields