Abrasive Polishing & Finishing Supplies

You’re working with challenging materials like metal, glass, and ceramic. The final polish is everything, and achieving that perfect, functional surface requires the right tools. Advanced Abrasives gets you the professional-grade polishing pads, compounds, and films to get the job done right.

Our Mission

To provide our customers with state-of-the-art superabrasive and related products. We are guided by the highest principles of integrity, honesty, commitment, and accountability in all our endeavors and decisions. We work closely with our customers to deliver superior quality products in a timely, cost-effective manner, all within a controlled environment. Our results-driven service philosophy and unwavering attention to detail result in world-class, industry-leading solutions that help our customers.

Beyond “Smooth”—Achieving a Flawless Surface

Anyone can make something feel smooth. You, however, need to create a surface that is truly flawless on a microscopic level. This means removing all previous machine marks, eliminating surface defects, and achieving a specific level of reflectivity or clarity. It’s about performance, and not just appearance.

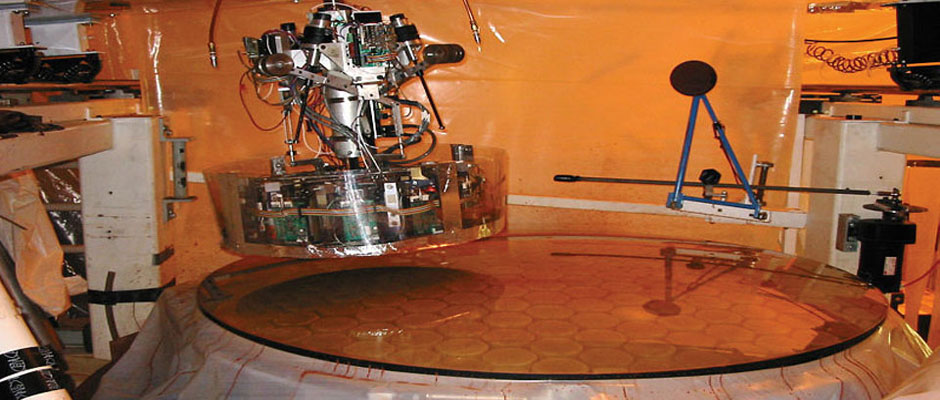

This level of superfinishing isn’t accomplished with a single tool. It’s a system of precision supplies working together. From the backing on a polishing pad to the particle size in a diamond compound, every element plays a role. We connect you with the components you need to build a polishing process that delivers consistent, exceptional results.

Your Material Dictates Your Tools

You wouldn’t use the same approach to polish a steel mold as you would for a delicate fiber optic lens. The material you are working with is the single most important factor in choosing your polishing supplies. A hard material requires a hard abrasive, while a softer material needs a gentler touch to avoid damage.

Hardened steel, ceramic, and sapphire demand the cutting power of a diamond compound. For softer metals, an aluminum oxide or silicon carbide slurry might be the perfect fit. Finishing delicate glass optics requires specific polishing pads that hold the abrasive just right, preventing scratches and sub-surface damage. Matching the supply to the material is the first and most important step to a great finish.

Putting the Right Supplies to Work

The demand for perfectly finished surfaces spans a huge range of high-tech industries. The quality of the polish often directly impacts the performance, safety, and longevity of the final product.

Here is where our clients use these finishing supplies every day:

- Medical Manufacturing: Creating a bio-compatible, ultra-smooth finish on metal surgical implants and tools.

- Precision Engineering: Polishing ceramic mechanical seals and valve seats to form perfect, leak-proof connections in piping systems.

- Optics and Photonics: Performing the final polish on glass lenses, prisms, and fiber optic connectors to maximize light transmission.

- Mold & Die Making: Finishing tool steel molds to a mirror shine for flawless plastic injection molding.

Why Quality Supplies Matter More Than Elbow Grease

Using low-grade or inconsistent polishing supplies is a recipe for frustration. You can spend hours working on a part only to find a random scratch that forces you to start over. Contaminated abrasives or poorly made pads lead to bad results, rejected parts, and wasted time.

High-quality finishing supplies remove that uncertainty. When you use a pad that’s built to last and a diamond compound that is precisely graded, you get a predictable outcome. The process becomes repeatable. You work faster, with less rework, and you can trust that the final surface will meet every specification.

Get the Finishing Supplies Your Work Deserves

Advanced Abrasives is your direct line to the industry’s most effective polishing and finishing products. The final quality of your work is a reflection of the materials you choose. We provide the world-class supplies you need to turn a good surface into a perfect one.

When your work demands precision, explore our complete catalog of finishing solutions: